Minneapolis Micro Leakage Meter (MLM)

Airtightness testing of ventilation duct systems according to DIN EN 12599

The Minneapolis Micro Leakage Meter (MLM) Measuring System has been developed by the manufacturer The Energy Conservatory in close cooperation with BlowerDoor GmbH in order to guarantee the functionality of ventilation systems by conducting airtightness tests of the duct system. With a measuring range of 0.17 to 78.5 m³/h, the MLM is also suitable for testing building components as well as small and highly airtight clean rooms.

The airtightness of the ventilation ducts installed is an important requirement for the functionality and efficiency of ventilation systems. Leakages in the ductwork impede the targeted distribution of air in the building. Consequently, the high level of air quality planned is not achieved. Leaky ventilation ducts impair the efficiency of ventilation systems, in particular of those with heat recovery. The Minneapolis Micro Leakage Meter allows you to reliably detect and locate leakages in the ductwork of ventilation systems and to eliminate them during the quality assurance process.

Special Measurements

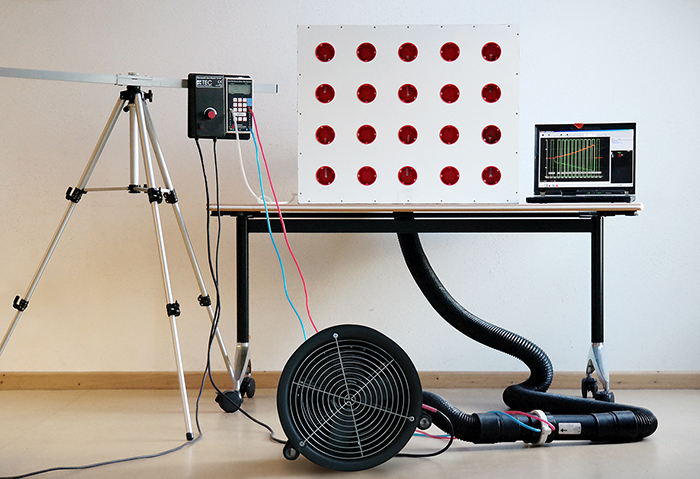

For the airtightness tests of ventilation ducts, the Micro Leakage Meter is used together with the DuctBlaster fan, the pressure gauge, and a speed controller. With the respective additional equipment, you can also conduct airtightness measurements with very low air flows:

- Airtightness measurements of highly airtight rooms (e. g. clean rooms)

- Measurements of joint permeability of windows and building component

The measuring principle

The ventilation systems are tested by ventilation strands. When testing the supply air ducts, the MLM is, for example, connected to the supply air valve. All other valves and the supply air duct at the central unit are closed with rubber bladders.

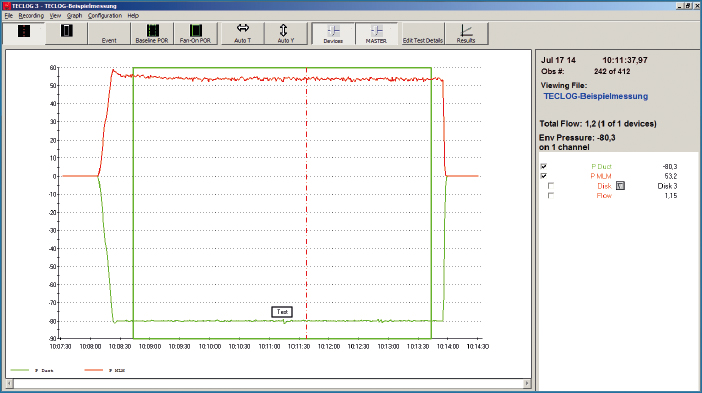

Using the Minneapolis DuctBlaster fan and the pressure gauge DG-1000 (included in the BlowerDoor MiniFan System) negative (testing exhaust air ducts) or positive (testing supply air ducts) pressure is created. The measuring results are documented in the test report.

Contact us:

Alexander Kiß is pleased to assist you!

Phone: +49 (0)5044 / 975-40

E-Mail: kiss@blowerdoor.de